Precision Gear Manufacturing

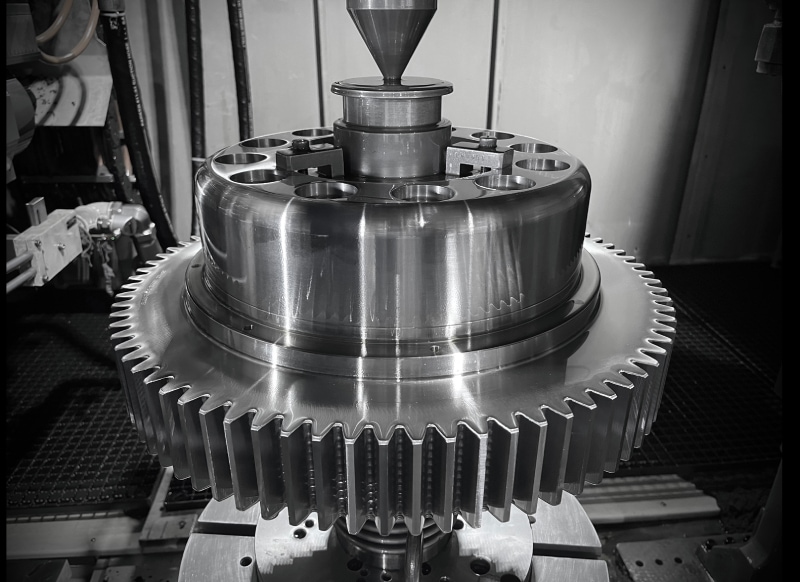

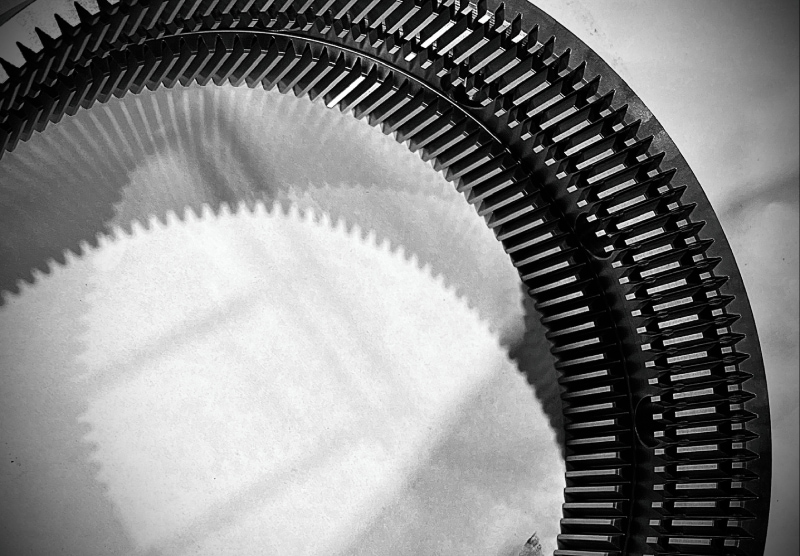

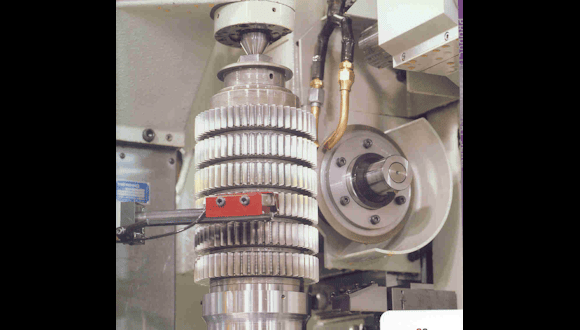

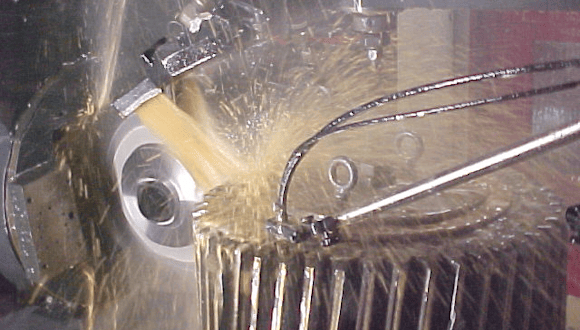

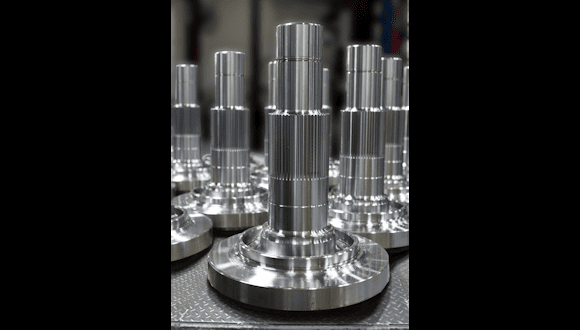

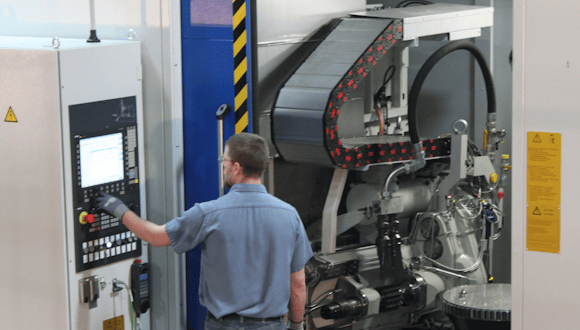

Consistently delivering ground gearing as high as AGMA level 15 (DIN 2 and ISO 2) requires state-of-the-art machining technology as well as time-honored craftsmanship. A variety of machining equipment gives us the versatility to handle both generative and form grinding processes, including CBN grinding. Columbia Gear’s reputation for precision grinding has been earned through years of performance for some of the world’s largest manufacturers — with the most demanding quality standards.

Maintaining this level of customer satisfaction requires a special combination of talented people and technology – and our commitment to both has never wavered. In fact, providing the best people with the best tools has always been the foundation for Columbia Gear’s longstanding record of customer satisfaction.

Productivity on Every Scale

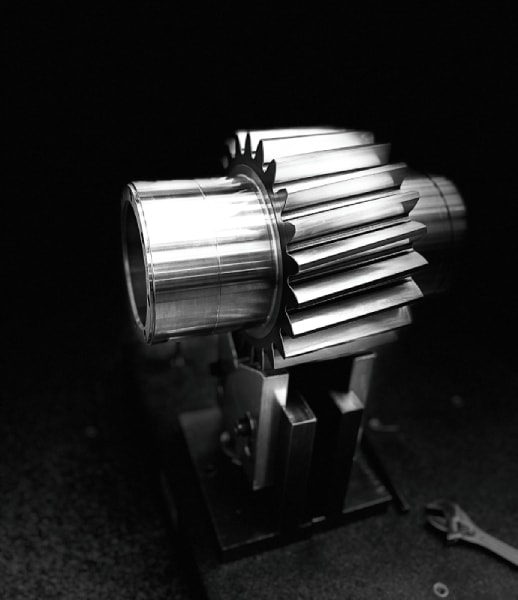

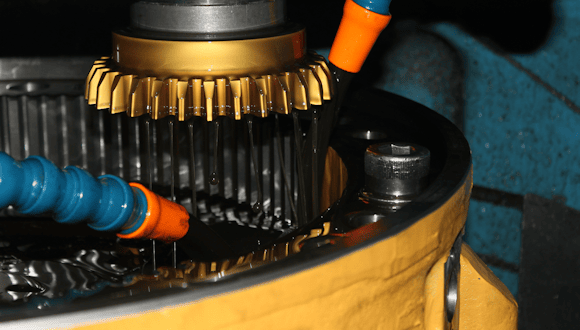

Among the industry’s finest, Columbia Gear’s grinding equipment is capable of producing even the most demanding helical and spur gear challenges. Capabilities include both generative, internal and external form and CBN grinding.

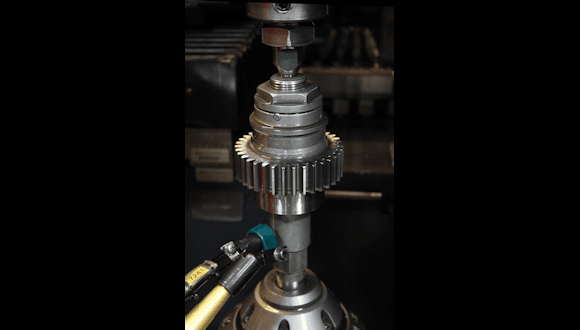

Gear Making Capabilities Include: Milling, Hobbing, Gear Grinding, Gear Cutting, Spline Rolling, Internal Gear Grinding, Precision Grinding to AGMA 15, Gear Crowning, OD and ID Cylindrical Grinding, Gear Shaving, Gear Shaping, Gear Gashing, Horizontal and Vertical Broaching, Hard Turning (to 62 Rockwell), High RPM Compressor Gears, Reduction and Up-Speed Gears

Just some of our complex gear types include Spur, Helical, Splines and Sprockets